Corrosion protection

Corrosion Guidebook – Part 2

After we have dealt with the different Types of corrosion in the first part of the corrosion guide, the second article will talk about the possibilities of preventing corrosion damage.

Corrosion protection includes all measures that help to avoid corrosion damage to metallic components. In addition to corrosion-resistant materials, there are many coatings that increase the level of corrosion protection. Let's look at these options in detail:

Stainless steels form a self-restoring surface layer, the passive coating. This protects the base material from corrosion. A sufficient oxygen concentration is necessary to create a passive coating.

Different types of stainless steel are used in fastening technology, depending on the field of application. The following types of stainless steel are used particularly frequently:

The use of corrosion resistant raw material is therefore one of the ways to reduce corrosion damage.

Corrosion protection includes all measures that help to avoid corrosion damage to metallic components. In addition to corrosion-resistant materials, there are many coatings that increase the level of corrosion protection. Let's look at these options in detail:

Selection of the raw material

Raw materials that prevent corrosion include, for example, non-ferrous metals and rust- and acid-resistant steels. The latter are also commonly referred to as "stainless steels". The materials for screws designated as corrosion resistant include, among other things, the corrosion-resistant stainless steels according to DIN EN 3506 and the national building authority approval Z-30.3-6.Stainless steels form a self-restoring surface layer, the passive coating. This protects the base material from corrosion. A sufficient oxygen concentration is necessary to create a passive coating.

Different types of stainless steel are used in fastening technology, depending on the field of application. The following types of stainless steel are used particularly frequently:

- Stainless steel type A2 (V2A) and A4 (V4A)

The steels are characterised by good corrosion resistance in moderately aggressive atmospheres (e.g. moist, salty air in coastal regions). - Stainless steels type HCR (e.g. 1.4529)

They have an extremely high corrosion resistance in the area of stainless steels and are suitable for very aggressive atmospheres (e.g. chlorinated water in swimming pools).

The use of corrosion resistant raw material is therefore one of the ways to reduce corrosion damage.

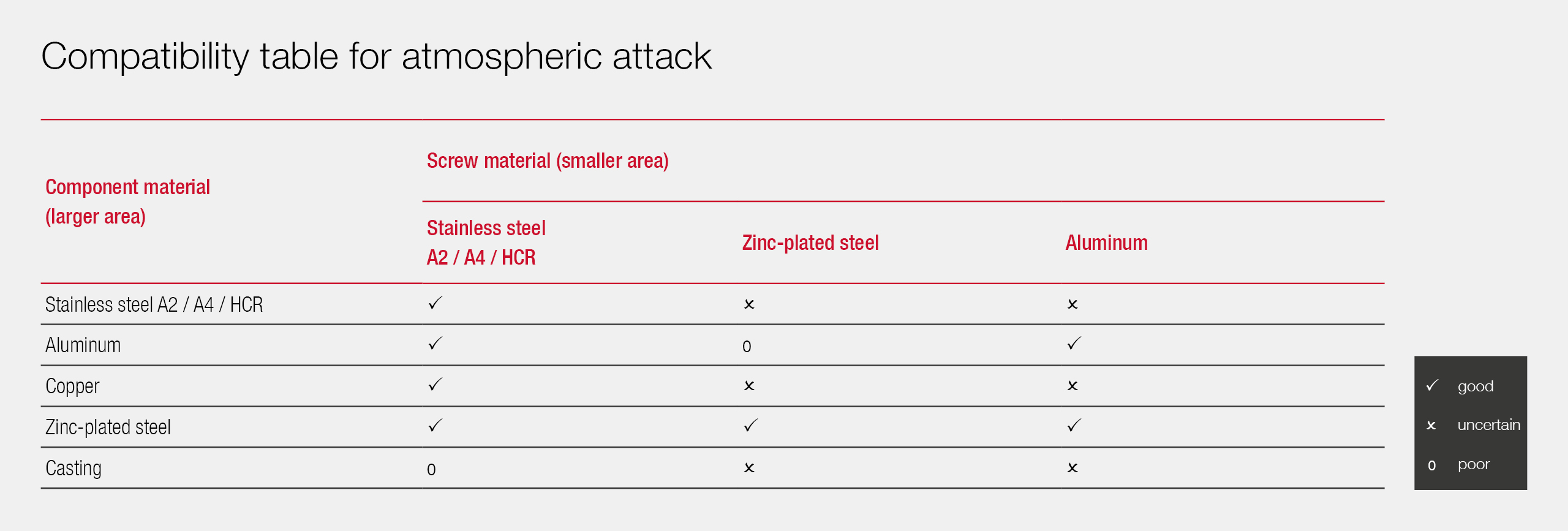

Note on the combination of different raw materials

When combining corrosion resistant raw materials, we must pay special attention to the Bimetallic corrosion, as not all raw materials are compatible with each other. Table I lists typical construction materials that can be combined with fasteners made of corrosion resistant stainless steels.Selection of the coating

With a suitable coating, a surface is considered to be "corrosion protected". The use of such coating is another way of reducing corrosion damage.Surface coatings for screws are assigned to non-metallic and metallic surfaces.

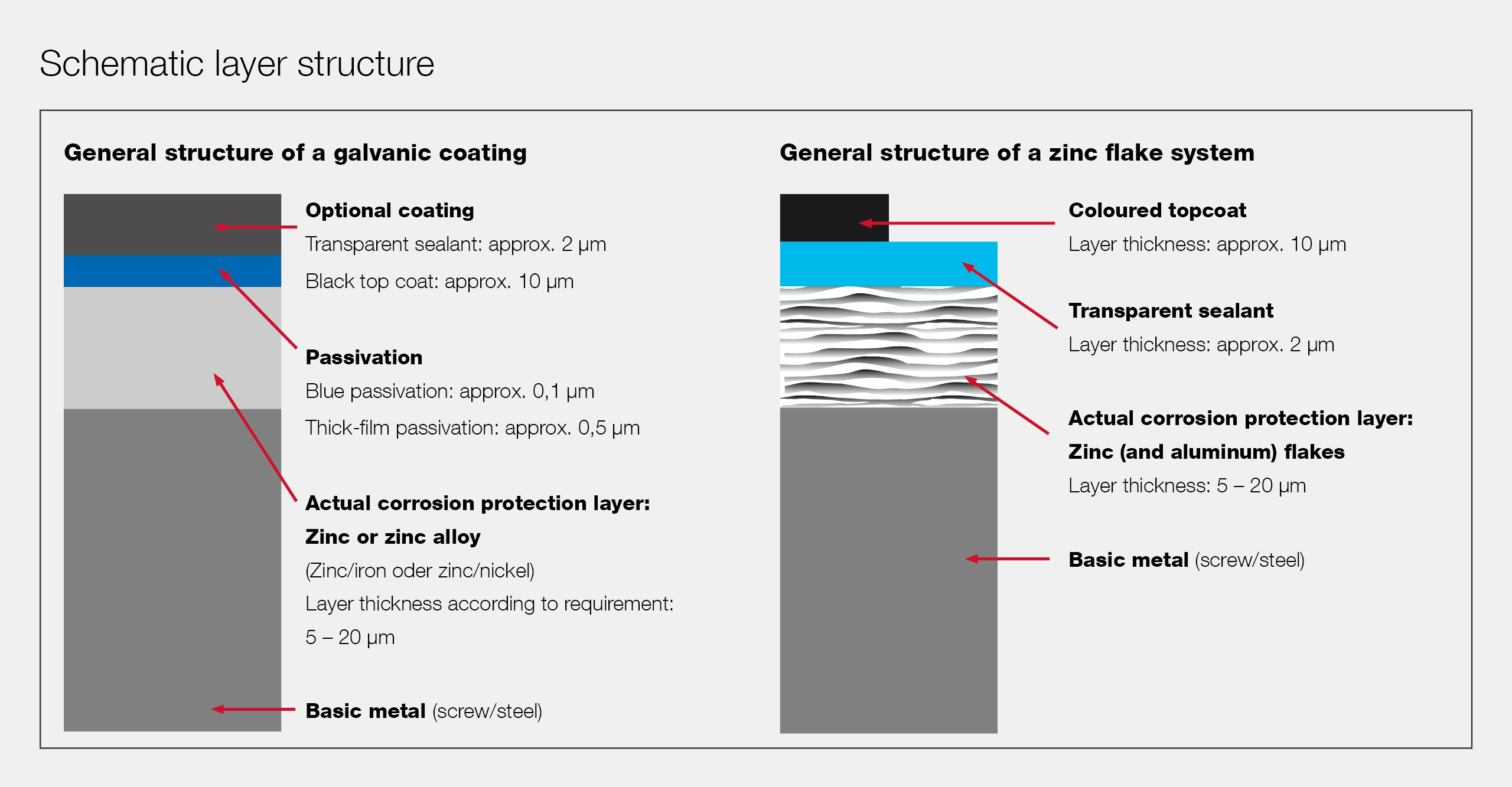

So-called galvanically applied coatings or zinc lamella coatings are generally used to protect metallic surfaces in order to increase corrosion protection:

Galvanic zinc plating

The most common metallic coating for fasteners is galvanic zinc plating (5–10µm) with subsequent passivation. For galvanizing, the workpieces are immersed in a zinc electrolyte and chemical and electrochemical processes take place. In the subsequent passivation phase, an additional protective layer is created on the metal, which prevents or greatly slows down corrosion.The subsequent sealing with a so-called topcoat protects the zinc layer from the White rust corrosion and additionally increases the corrosion protection.

Overview of the performance features and advantages:

- Versatile application range

- Cost-effective process

- Resistant against environmental influences

- Protection against damages during transport, setup and service

- High corrosion resistance

- Excellent further processing

Zinc lamella coating

Zinc lamella coating is a non-electrolytic coating, which consists of a so-called inorganic basecoat and a topcoat.The basecoat can be a zinc lamella coating, which consists predominantly of zinc and aluminium lamellae. It is applied directly to the metal part. This base coat determines the anti-corrosive properties. The zinc it contains provides a high level of cathodic protection against corrosion. The topcoat (sealing) additionally complements the properties of the basecoat. In addition to corrosion protection, this top coat protects against chemical and mechanical effects and is responsible, for example, for weather resistance and appearance. The combination of both is called Duplex-coating.

Overview of the performance features and advantages:

- Long-term corrosion protection under cyclical loads

- Delayed red and white rust formation and galvanic corrosion

- No hydrogen embrittlement

- Chemical resistance

- Thin coating thicknesses (6 - 25 µm) possible

- Heat resistance (180 - 300 °C depending on the product)

This process is used wherever excellent corrosion protection is to be combined with other functional and decorative properties.

Zinc lamella corrosion protection was originally designed as a chrome VI-free alternative to galvanizing. It has established itself due to the wide range of possible uses for a wide variety of applications.

In addition to galvanizing and zinc lamella coating, there are other types of coating. These include hot-dip coatings such as hot-dip galvanizing and mechanical coatings. However, due to the partially high layer thicknesses, these are less suitable for self-tapping and self-drilling screws in the construction sector.

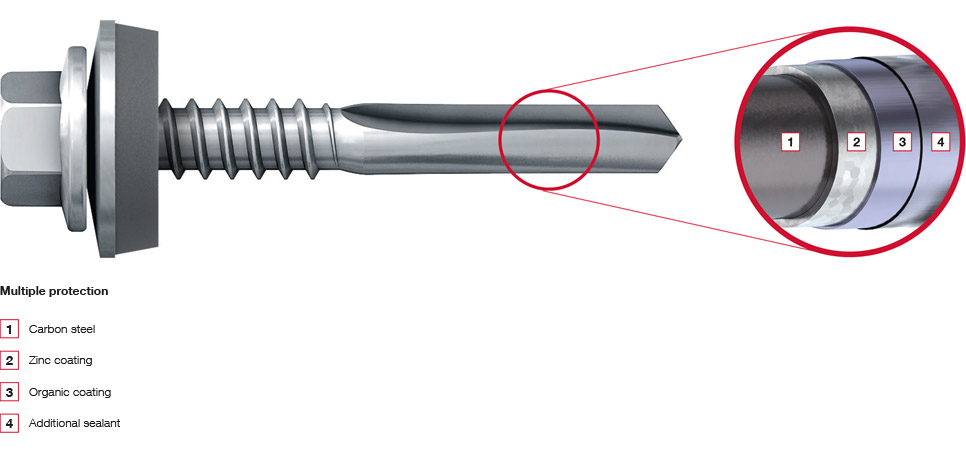

In addition to galvanic coatings in accordance with DIN EN 4042 and zinc lamella coatings in accordance with DIN EN ISO 10683, the duplex coatings C 1000, CLIMADUR and EJOGUARD are used for products from EJOT.

Thanks to the combination of specially coordinated coatings, the EJOGUARD surface offers excellent corrosion properties. With a resistance of one thousand hours in the salt spray test according to DIN EN ISO 9227 and 15 test cycles passed in the Kesternich test (corrosion test with sulphur dioxide and water) according to DIN 50018, the application range of steel screws is significantly expanded depending on national regulations.

In addition to galvanic coatings in accordance with DIN EN 4042 and zinc lamella coatings in accordance with DIN EN ISO 10683, the duplex coatings C 1000, CLIMADUR and EJOGUARD are used for products from EJOT.

Thanks to the combination of specially coordinated coatings, the EJOGUARD surface offers excellent corrosion properties. With a resistance of one thousand hours in the salt spray test according to DIN EN ISO 9227 and 15 test cycles passed in the Kesternich test (corrosion test with sulphur dioxide and water) according to DIN 50018, the application range of steel screws is significantly expanded depending on national regulations.