Avoid assembly errors with self-drilling screws

Guide to self-drilling screws – Part 5

Our EJOT self-drilling screw guide has already dealt with different types of self-drilling screws, the different head styles and drive types, manufacturing processes and the edge distances to be taken into account when using self-drilling screws and thread-forming screws.

The current part of the self-drilling screw guide is now devoted to avoiding damages that can occur due to improper assembly.

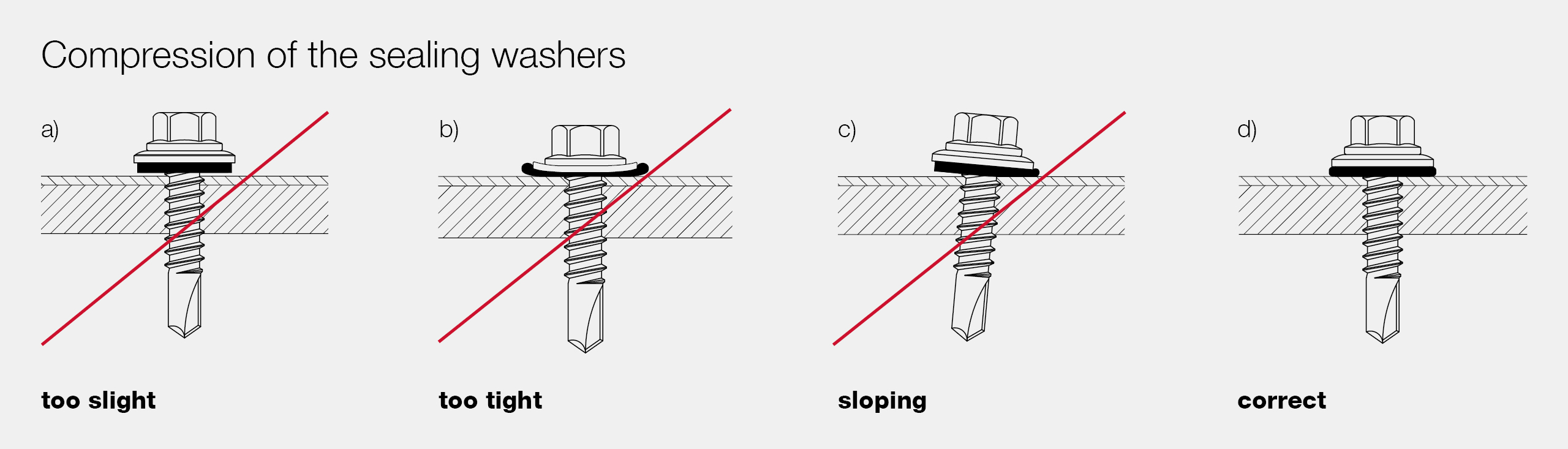

If the screw with the sealing washer has not been tightened enough, it is too loose (a) and tightness cannot be guaranteed. On the other hand, if it is tightened too much, the sealing washer bulges out (b) and the inner lip seal (EPDM) can be damaged. Tightness cannot be guaranteed either. Care must also be taken to ensure that the screw connection is straight. An inclined screw connection (c) cannot provide the desired tightness either. If the sealing washer is correctly installed, the sealing rubber may protrude from the side (d). The joint is definitely too tight only if the metal back of the sealing washer changes from convex to concave.

The current part of the self-drilling screw guide is now devoted to avoiding damages that can occur due to improper assembly.

Tightening the sealing washer

Sealing washers are always used in construction when a screw connection is to be protected against the penetration of moisture and dirt or to distribute the existing clamp loads over a larger area than that of the screw head. The clamp load and thus the tensile stress in the screw are limited by the use of sealing washers. Direct outdoor exposure of the fastening point is virtually prevented - the risk of an operational, hydrogen-induced embrittlement (you can find an interesting article on this topic here) is significantly reduced. The risk of incorrect assembly (including excessive tightening torque or slightly inclined tensioning) with a screw connection is significantly reduced by using sealing washers. Screws with sealing washers must be installed using depth control. The depth stop can be set by using a suitable drill and inadmissible deformation of the sealing washer (washer with elastomer seal) can be prevented.If the screw with the sealing washer has not been tightened enough, it is too loose (a) and tightness cannot be guaranteed. On the other hand, if it is tightened too much, the sealing washer bulges out (b) and the inner lip seal (EPDM) can be damaged. Tightness cannot be guaranteed either. Care must also be taken to ensure that the screw connection is straight. An inclined screw connection (c) cannot provide the desired tightness either. If the sealing washer is correctly installed, the sealing rubber may protrude from the side (d). The joint is definitely too tight only if the metal back of the sealing washer changes from convex to concave.

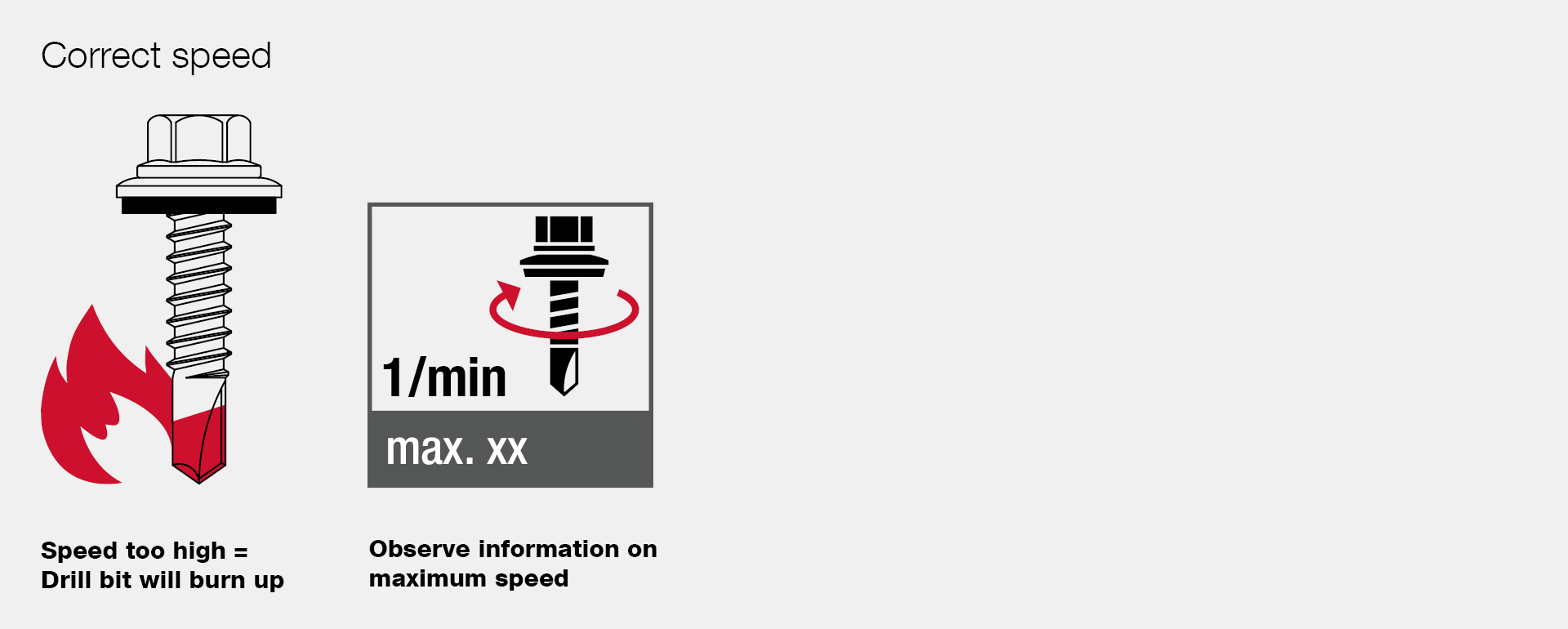

Correct speed

Self-drilling screws have the advantage that they can be processed particularly quickly as there is no need to pre-drill. The correct speed depends on the type of screw. As a rule of thumb, the smaller the screw diameter, the higher the speed and the lower the contact pressure. Larger screw diameters, on the other hand, are processed at a lower speed and higher contact pressure.If the selected speed is too high, there is a risk that the drill bit will burn up and become unusable. If the speed is too low, chip removal cannot be guaranteed. The screw becomes clogged, the time required for assembly increases or, in the worst case, assembly cannot be carried out at all.

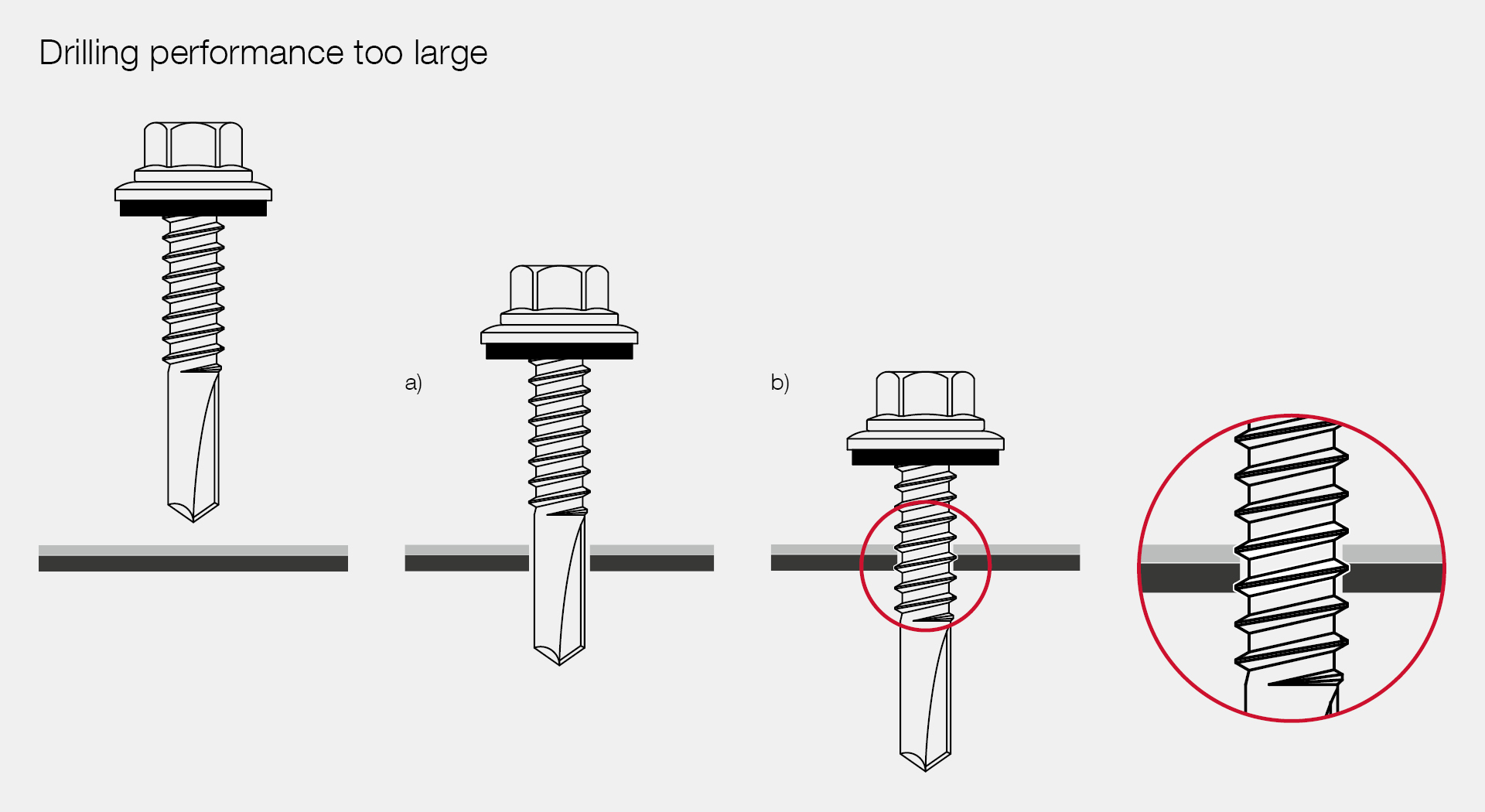

Selection of a suitable drilling performance for the application

The drilling performance of a screw refers to the drill point and defines the maximum thickness of components which can be penetrated with this drill point. The drilling performance value ≥ t is stated in millimetres.Regarding the drill point diameter and drill point length, Self-drilling screws with higher drilling performance are only designed for components of greater thickness. When using a self-drilling screw with too high a drilling performance, the drill point diameter (a) and thus the drill hole produced is too large and the flank coverage (b) is too small. In addition, there is no security against turning back that could prevent the screw from being unintentionally loosened and the tightness from being lost. As a result, a secure connection cannot be established. Such assembly is therefore not permitted.

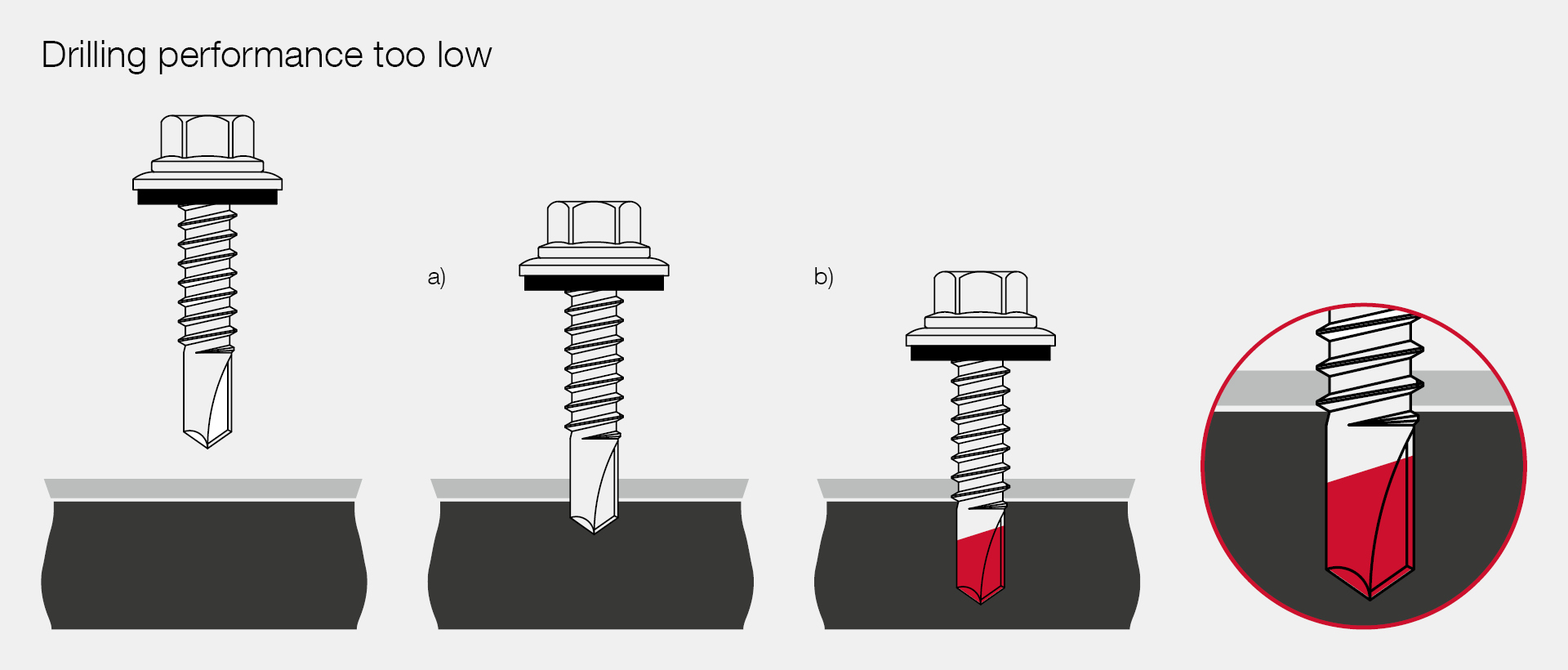

If the drilling performance (alternatively also called drilling capacity) is too low (a), the screw is forced to advance during the drilling process. The forced advance occurs when the drilling process has not yet been completed, but the thread of the screw is already engaged (b). At this moment, the feed generated by the thread pitch is greater than the feed that can be achieved by removing the chips during the drilling process. As a result, too much force is exerted in the direction of the screw axis and the drill point burns up. The drill point of the screw becomes blunt and cannot complete the “drilling” operation.

Selecting the right screw

It is particularly important to ensure that the correct type of self-drilling screw is selected for wall applications. A distinction must be made between JT screws (classic drill point with cutting edge) and JF screws (unique tip geometry without cutting edge).The unique tip geometry of the JF screws enables an improved application behaviour on the component surface compared to classic self-drilling screws. The risk of the screw wobbling on the cover shell and thus damage due to scratches is reduced to a minimum. The unique tip geometry significantly increases the speed of penetration of thin sheet metal.