Edge distances of self-drilling screws and self-tapping screws

Guide to self-drilling screws – Part 4

Edge distances of self-drilling screws and self-tapping screws

In the previous parts of our self-drilling screw guide, we dealt with the different types of self-drilling screws, the different head shapes and drive types, as well as the manufacturing processes for self-drilling screws.This part now deals with the edge distances to be observed when using self-drilling screws and thread-forming screws in timber, steel and aluminum parts.

Fewer failures due to correct edge distances

Self-drilling screws and self-tapping screws can be used for various applications. The main area of application is fixing of profiled steel and aluminum sheets as well as sandwich elements in the roof and wall area of industrial lightweight construction. The substructures for the components mentioned are mostly thin-walled, cold-formed components made of steel and aluminum, as well as wooden components.The processing, requirements and dimensioning of these applications are regulated by technical rules, standards and approvals. An important point when using fasteners is adherence to the necessary edge distances. Failures due to gaps in wooden components, as well as slotted holes and cracks in sheet metal parts can be prevented in this way.

Where can I find information on the necessary edge distances?

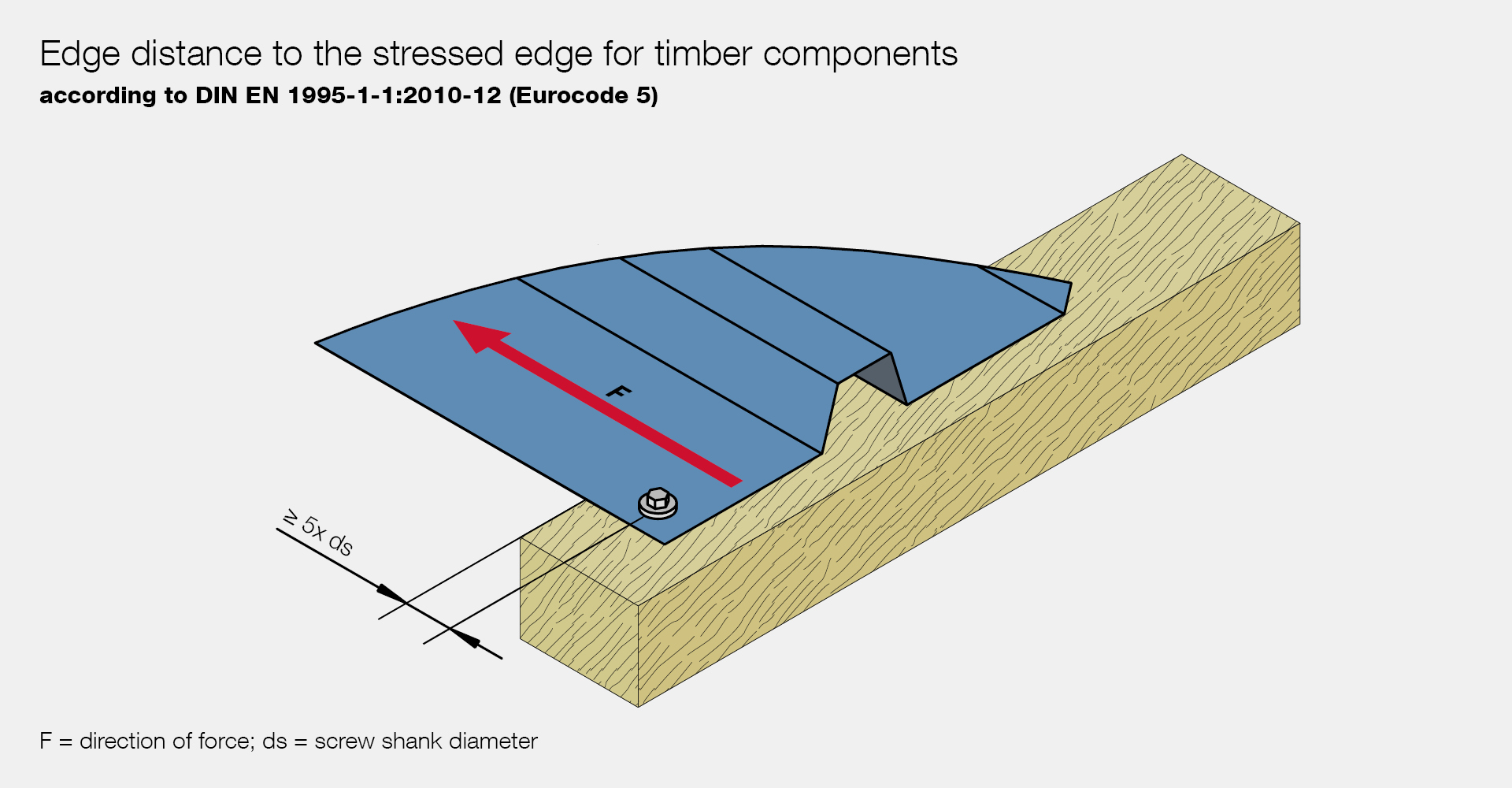

Information is provided in the standards for dimensioning the different components. Different standards are used here, depending on the type of material.Wooden Components

Information on the necessary edge distances in wooden components can be found, for example, in DIN EN 1995-1-1: 2010-12 (Eurocode 5).There are various parameters to consider, which have an influence on the required edge distance:

- Direction of the grain of the wood

- Angle between force and grain direction

- Loaded / unloaded edge

- Screw diameter

- Using pre-drilled / non-pre-drilled screws

The EJOT JF and JT screw types are generally considered to be pre-drilled when calculating the edge distances. The only exception is the JA screw type, these screws must be pre-drilled (0.7xd). Therefore, only the formulas for the minimum distances with pilot hole in accordance with DIN EN 1995-1-1: 2010-12 need to be taken into account.

However, the extensive tables and representations of DIN EN 1995-1-1: 2010-12 quickly make it clear that the necessary edge distance cannot be determined without special knowledge in relation to the timber construction standard.

If you have any questions about the correct calculation of the necessary edge distances, the EJOT Technical contactexperts are happy to provide advice and assistance.

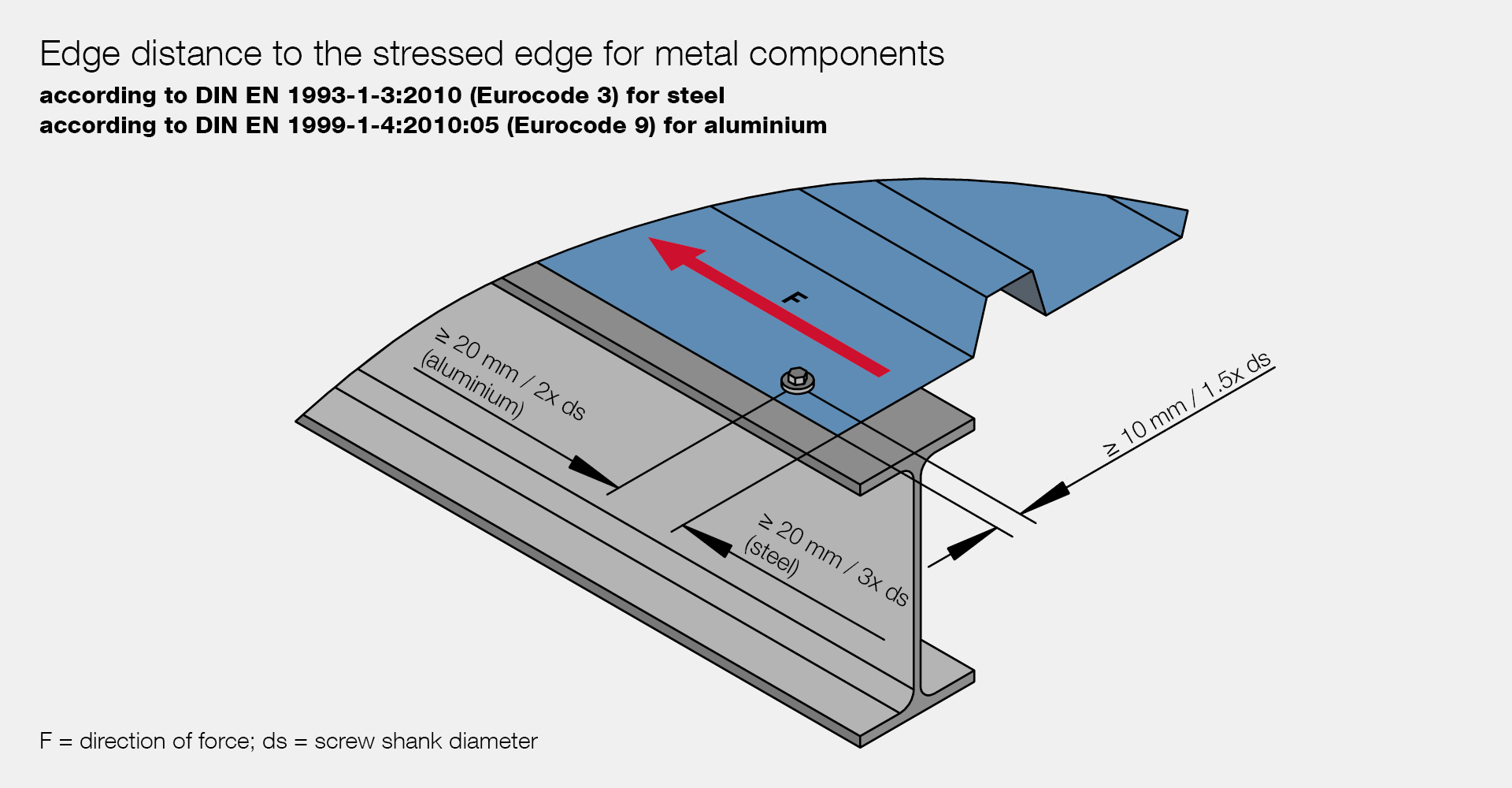

Steel and aluminium components

It is easier to determine the edge distances when using steel and aluminium components. DIN EN 1993-1-3: 2010 (Eurocode 3) regulates the edge distances for thin-walled steel components.

The only parameters to be considered are:

- Screw diameter

- Differentiation between loaded / unloaded edge

- Direction of the force

It is just as simple with thin-walled aluminium components. Here you can find the information in DIN EN 1999-1-4: 2010: 05 (Eurocode 9) summarized in one representation.